We have explained in the chapter of the sustainable fashion business model in #Metaverse about 4 conditions that the output data must meet to realize the true virtual and reality interaction business mode of apparel industry.

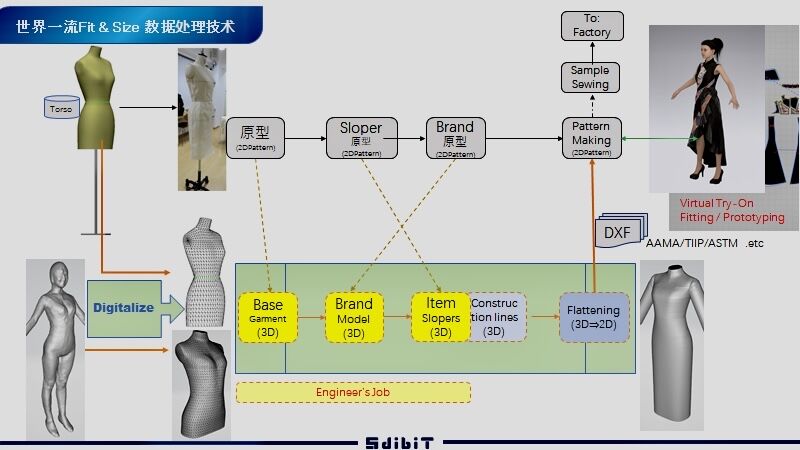

1. Suitable methods of Vhuman and 3D Digital Torso establishment

2. 3D digital garment model establishment based on above 1, and output of the 2D production pattern converted from setting cutting lines on the 3D digital garment model

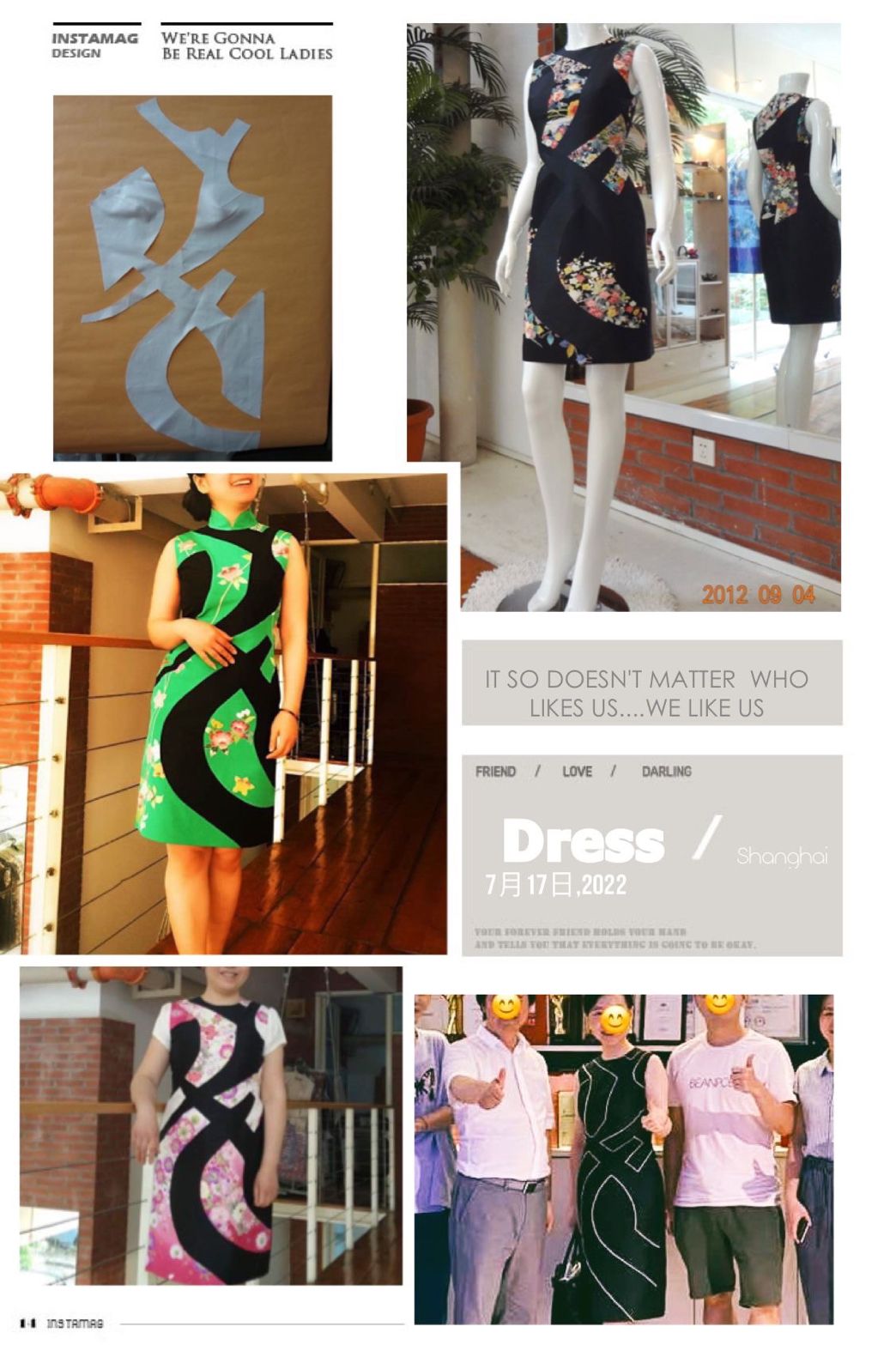

3. Interchangeable application based on modular design and repurposed design management

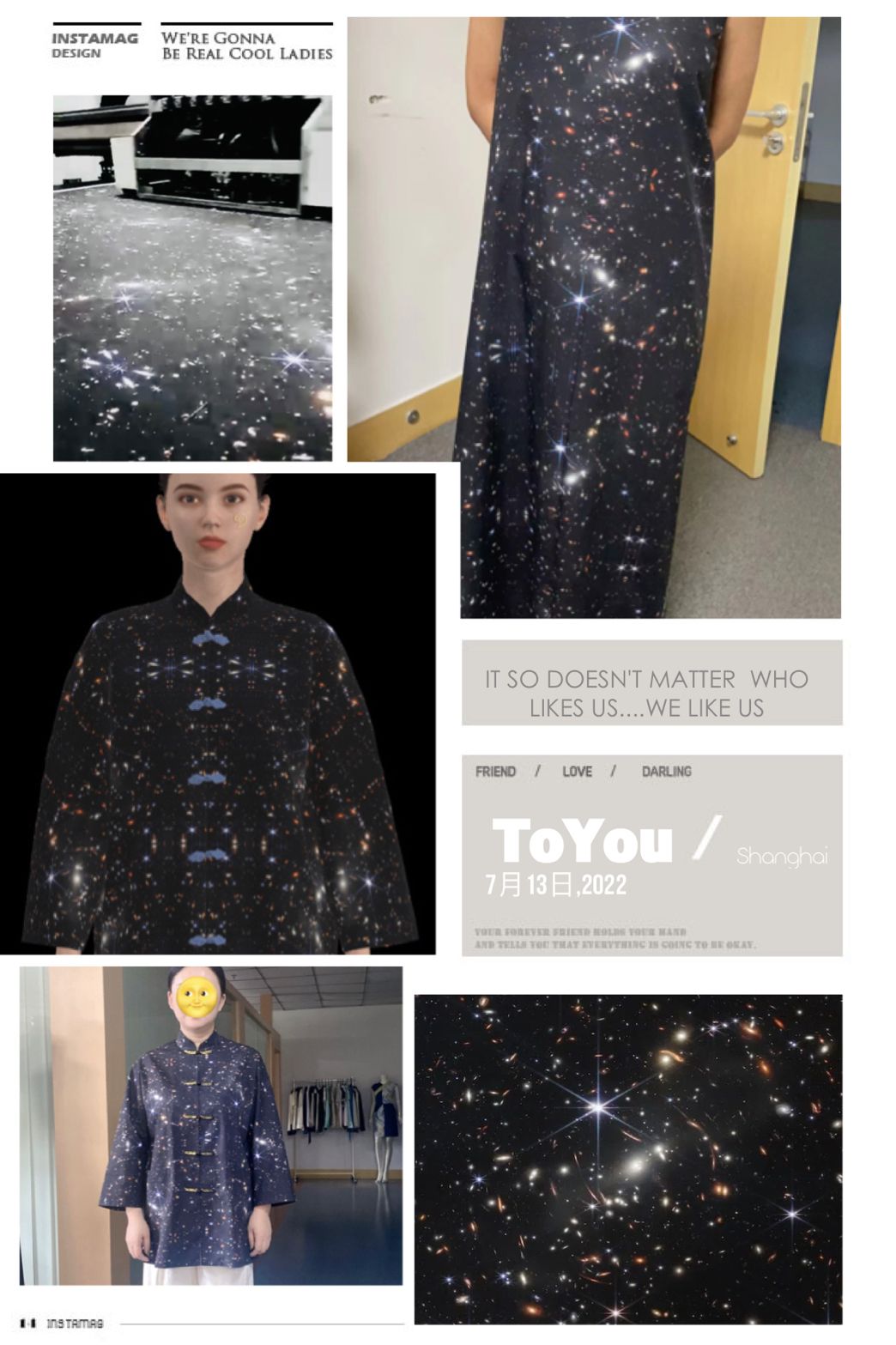

4. Integration of digital fabric and 3D-design

Although the software tools involved in the above four conditions have various problems, SdibiT can make the output data meet the above 4 conditions as this is proved by more than 10 years’ practice and technical logic.

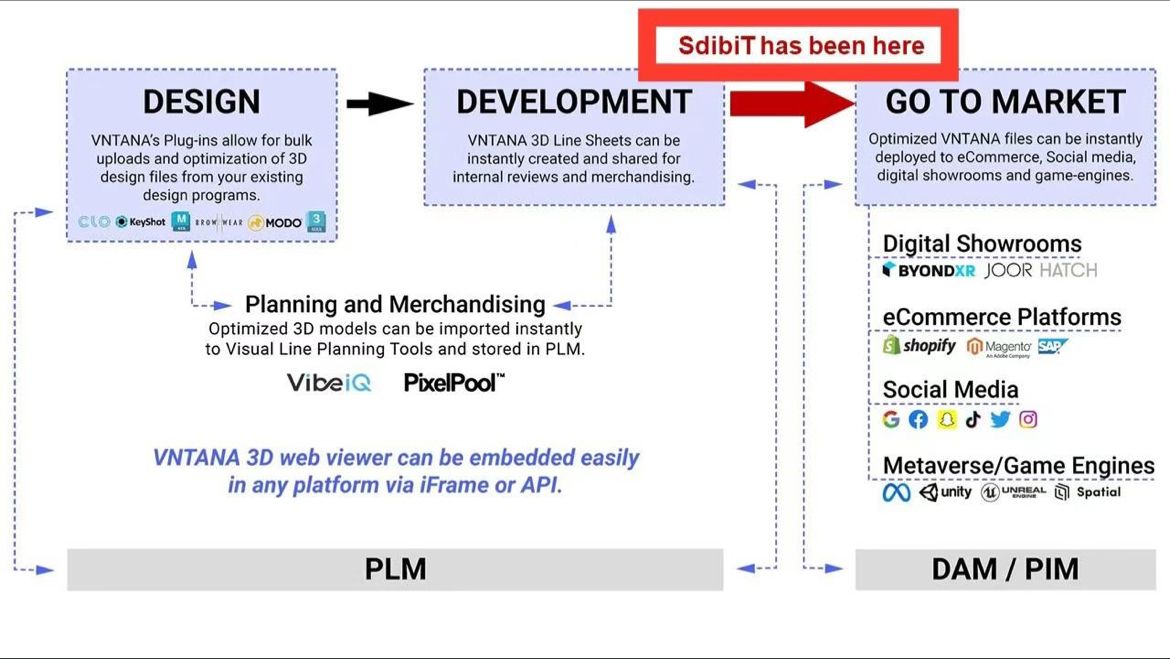

This means that no matter the future clothing display orientation is AR、VR、MR…if adopting SdibiT’s solution, the basic data input to the display end is the same. And SdibiT can provide such data for customers to use according to their own optional display method.

That is to say, no matter which direction the industry will go in the future, we have made basic preparation to provide corresponding data.

Here we compare the competition of the apparel industry, which is about to soar, to a new event of the Olympics. The event participant must meet 4 conditions. In each single item competition, SdibiT may not be the top one, but SdibiT is the only one who meet all 4 conditions currently, so we will always be the champion of this new event until there is another contestant who meets all 4 conditions too.

SdibiT holds the willing to facilitate the truly sustainable development of apparel industry worldwide and be a respected environment friendly enterprise. Therefore, we’d like to align with others to participate in the team competition. In technology competition, time is the most expensive cost. Any part who is willing to adopt our solution can make up the shortage and be prepared to participate in the event together within the shortest time, jointly carry forward this event worldwide.

Two days ago, a friend introduced me to a young investor from China who was listed as one of the 2018 Forbes U30 Excellent Investors. He mainly invested in China’s semiconductor projects. Although he is not familiar about fashion industry, he raised doubts about us with his rich investment experience. He took examples of #Anta, #Alibaba’s rhino platform, etc.

These giant enterprises have thousands of stores online and offline and accept numerous customers every day. Their daily customer number can be ten years’ accumulation of some foreign brands.

And scanning technology is quite common now. Besides human body scanner, sellers can also use iPhone to scan customers to get their 3D avatar.

So it is easy to get enough human body big data.

In terms of the scan and modeling quality, there are technologies using to build cars, vessels and even smart cities, so the data and modeling quality can be ensured.

From the point of Vhuman and #Fit&Size alone, how can only small enterprises like SdibiT has the data that meet the necessary requirements for fashion virtual and reality interaction?

The giant enterprises have money, talents and customer data. Why do they not do it? Maybe they think it cannot bring expected benefits or they are already doing pretty well, such investment is needless.

I keep the words that the technology department of #Alibaba’s rhino platform had contacted us. Their obstacle is not #digital flexible production, but still is the digitization of design and pattern making.

As far as I know, to serve one brand, at least 2.8 pattern makers should be deployed. If 1000 brands on the platform require the same service, does Alibaba need to gather half of China’s pattern makers to work in the building?

Thanks to his frankness. The conversation makes me realize that the digital technology and knowhow involved in the process of fashion design and pattern making are not easier than shipbuilding, car building or modeling in smart cities.

Because the 3D virtual modeling of any other industry only needs to capture and simulate the physical object. No extra process is needed after virtual modeling.

For apparel digital design and pattern making, digital modeling of real human body is just the first step.

It is impossible to draw garment cutting lines directly on roughness 3D digital avatar.

It needs secondary processing with sense of aesthetics and proportion optimization to become a 3D Digital Torso, at least.

And then, we can start to draw #design cutting lines directly on 3D digital garment model created from the 3D Digital Torso.

The traditional apparel industry, through digital transformation, will be reborn into a very young and dynamic technology intensive industry.

Being belittled as a sunset industry is just because the short-sighted sunset thinking and the sunset apparel enterprises like boiled frogs in warm water are ubiquitous in reality.

Here, I’d like to pay a tribute to all the fashion digitization pioneers!

16th Oct, 2022