We believe the foundation of successful digital transformation in the design and pattern making process lies in the use of structural design, establishing various types of 3D Digital Garment Model in advance. Fashion brands can determine and establish 3D Digital Garment Models according to their own aesthetic criterion. What proportion is the most beautiful, what size and shape of each cross section should be, etc. But once the 3D Digital Garment Model is established, it can not be modified arbitrarily. It should keep stable as the DNA to brand to contribute to the accumulation and management of modularized and interchangeable design. Even the Models have to be modified due to change of body shape big data or target consumer group, they should be modified under the brand’s new criteria and keep stable for a long time.

And the application of these 3D Digital Garment Models should follow some standards. For example, the intersection point is fixed at the same position no matter how the cutting lines vary. This standardization management method requires modularized and compatible design on 3D Digital Garment Models. Such digital fashion design management mode is absolutely the core of our solution because this core can play following two key roles.

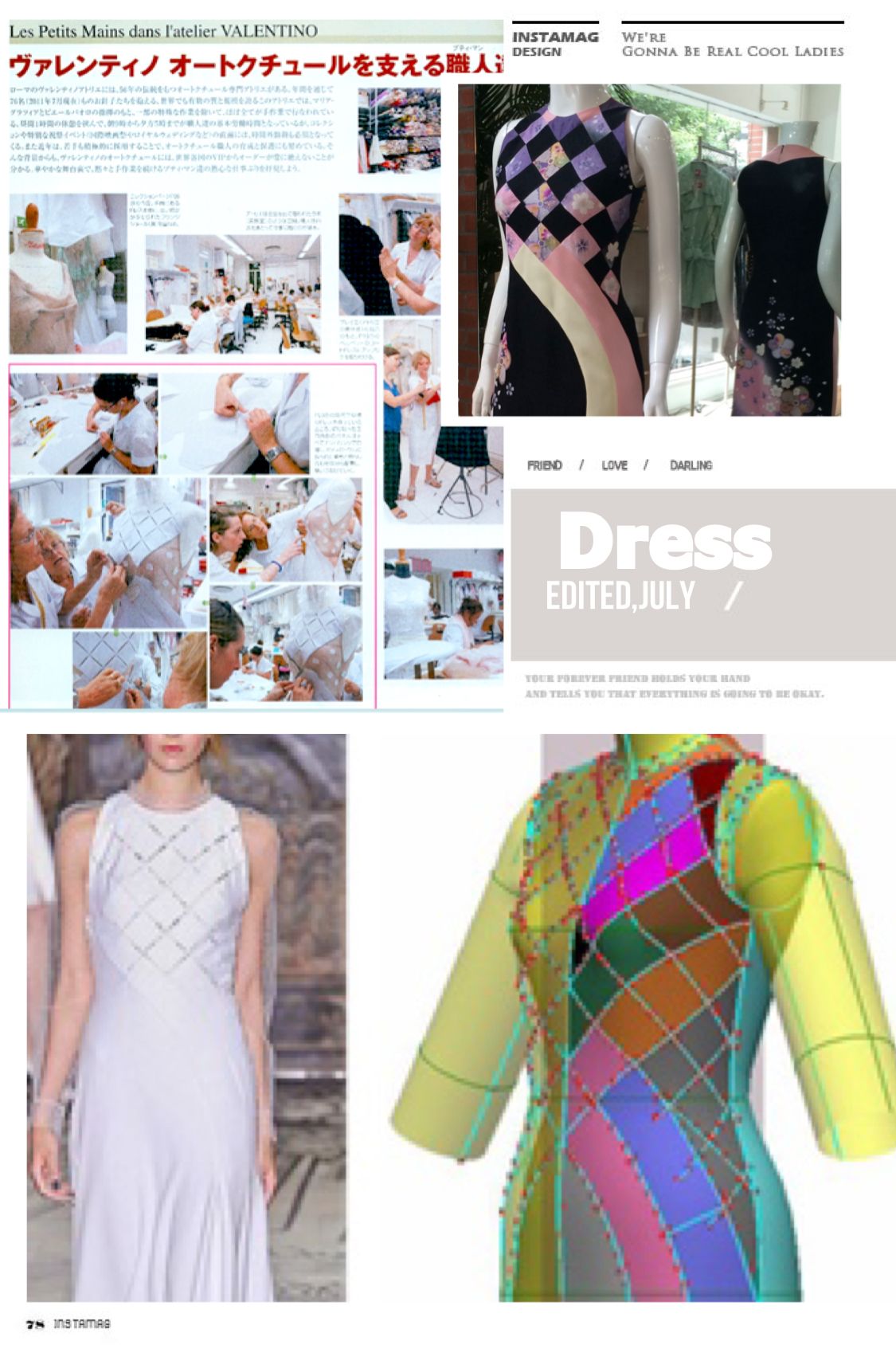

First, we think that the key of giving consumers’ unique impression of one clothing brand is establishing the brand’s identification, and the key is consistent style and brand value conveyed to consumers. No matter how different design elements, fabrics, colors and patterns match and mix with each other to generate various looks every season, the representative outer shape of clothes is as the brand’s DNA, the key to enhancing brand identification. Take these products in life for example, the Coca-Cola glass bottles, Porsche sports cars, Chanel tweed coats, etc, you will find the easily recognizable products all have one thing in common, consistent outer shape. Therefore, to accurately control the brand information transmit of clothing outer shape DNA, we do fashion design on unified 3D Digital Garment Model.

Second, the design and pattern-making phase is just like the brain center of the entire apparel industry chain, issuing instructions to the synergy operations downstream. The development level of the brain directly affects the comprehensive competitiveness of brands in the industry. In the commodity development process, the full sharing of creators collaboration can be achieved, through digitization, standardization and component interchangeable transformation of design and pattern making phase.

The video only shows the tip of the iceberg of changing clothing designs. If following our digital design processing and management method, clothing is like LEGO, from a single design, creators can build up thousands of different looks by combining standard digital components.

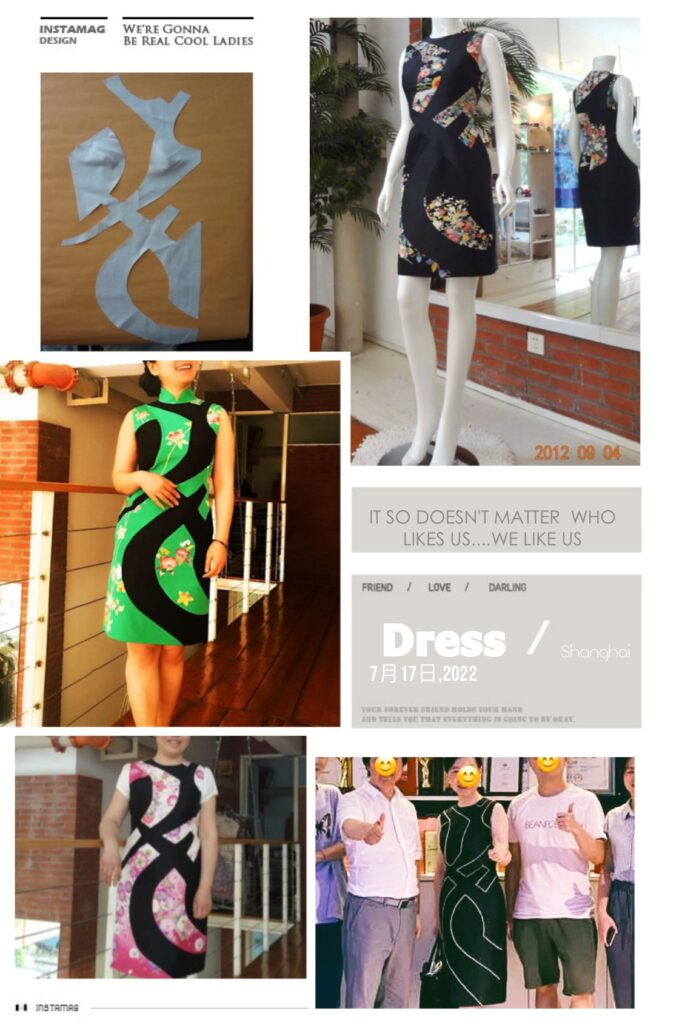

In previous submissions, we talked about if following our digital design processing and management method, clothing can be designed like LEGO.

Because information silos are eliminated, new design patterns can be automatically generated through unlimited exchange combination, so as to form the brand teams’ or enterprise’s unique standardized design database, and greatly shorten the design expansion cycle.

We have repeatedly stated that SdibiT’s solution focuses on consumers. SdibiT makes virtual clothes for people to watch and order online. All the virtual clothes people see online can be produced into ready-to-wear goods offline, and immediately delivered to end consumers in need.

The ideal style which the consumer expects is the purpose of our data output. Take a dress as an example, looking at the design drawings or commodity brochures, it is often that consumers like looks that are not completely same as what they have seen. They may like brandX’s collar +brandY’s sleeve, or brandA’s front +brandB’s back +brandC’s hemline, or even one of the cutting lines that appeared in brandV’s haute couture designs. And we just meet their needs through our solution.

There are two major changes that everyone must be aware of.

First, with our solution, standardized design database is dynamic and constantly expanding. In addition, as this expansion is no longer limited by time and space, new design data can be added by different people working in synergy.

In standardized design database, the growth rate of design materials is no longer calculated in the traditional way of addition, but exponential multiplication.

Secondly, according to the actual needs of end consumers, fashion creators extract various structural lines or design elements from the design database and continuously combine them to generate new design patterns. The definition of original in the traditional sense will be subverted. LEGO, for example, uses the same standard parts and combines them to form kaleidoscopic shapes.

Can these final appearances of LEGO be claimed by the creator to be original of his own idea?

17th Jul, 2022