The sustainable fashion industry forum held by SdibiT and XXY Innovation aims to discuss feasible measures that can drive fashion sustainability from comprehensive perspectives, introduce advanced technologies, share new design thoughts and encourage environmental friendly fashion consumption. The forum is supported by China Dragon Design Foundation.

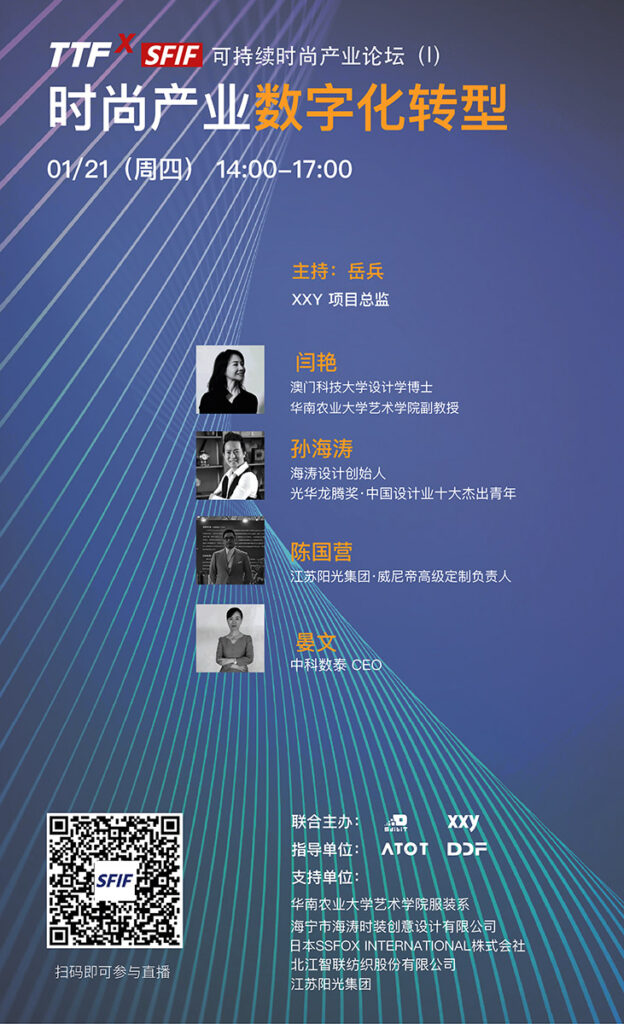

The theme of the first session held on 21st Jan 2021 is the digital transformation of fashion industry. SdibiT invited professionals from university, one of outstanding designers in China, managers in famous companies and observers who paid attention to the fashion industry. Specialized in different part of fashion, these people shared their own opinions about sustainable fashion from different perspectives.

Yan Yan, professor of College of Arts of South China Agricultural University, shared general concept, principle and theory of sustainable fashion. Application cases such as jeans that in compliance with the jeans redesign standard by Ellen MacArthur Foundation were also shared in detail to help audience understand the theory deeply.

Haitao Sun, famous designer, shared sustainable fashion as the core competitiveness for fashion design and fashion brand. He also emphasized the power of design to connect technology and market such as the application of O2O digital design platform.

Vincent Chen, manager of VENETIA, a made to measure brand belong to Jiangsu Sunshine Group Co,.LTD, shared the digital transformation measures taken in this giant fabric and apparel production company. The pattern big data, intelligent manufacture process and data flow management all plays an effective role in its technology update.

Wen Yan, CEO of SdibiT, a digital technology provider specialized in human body contour shape, design and pattern data and VR visual data, shared how to control the data-pipeline by 3D design and pattern making application. She also shared SdibiT’s subversive digital technology process which is different from the mainstream 2D → 3D prototype (virtual sample garment production) in the apparel industry. Different from personalization, the process is a real customization based on customer’s preference and body contour shape.

The decisive difference is the first stage of pattern making for generation of body trunk garment. No matter for which size, [2D pattern making method] and [2D grading method] are not used at all. The prototype of SdibiT is [3D (generate) → 2D → 3D (confirm)], named [Clone Shape Ensured Method] by us because of its extremely high 3D reproducibility of real clothes. Only by generating 3D virtual garment in advance, can we respond to evolving customization requirement of the market. And it is also an indispensable engineering step to fulfill the customization requirement.

High 3D reproducibility in clothes of different designs can reduce the returns or exchanges caused by “Fit & Size” in online shopping, and instead of just focusing on sales, turn fashion business to a more sustainable and appreciated mode. A mode in which consumers can design their own clothes and place the order after check the VR fitting, then the production begins only when receiving an order. Everyone in this business cycle makes contribution to environment protection at the same time.

Bin Yue, Project Director of XXY Innovation, a consulting firm, shared his opinion towards cooperation between different parts within the fashion loop.

After forum, a common opinion is achieved that more communication and further cooperation between every party is necessary.

If you want to know more about the content of the forum, please refer to the video record link below.